The management of industrial effluents—whether cutting fluids, quenching baths, grinding or polishing liquids—relies on efficient and controlled filtration.

To optimize bath quality, extend tool life, and reduce operating costs, it is essential to understand filtration threshold, absolute filtration, and their influence on TSS levels.

What is a filtration threshold? Simple definition and industrial applications

The filtration threshold refers to the minimum particle size that a filter medium can retain. Expressed in microns, it determines the fineness of the filtration.

In industry, useful thresholds are generally between 5 µm and 500 µm.

Why is this threshold essential?

Because it directly influences:

- the cleanliness of a cutting fluid,

- the stability of a quenching bath,

- the quality of grinding and polishing operations,

- the aging of machines and tools.

A 50-micron filter media removes most metal or mineral particles ≥ 50 µm, thereby improving the overall cleanliness of the bath.

Nominal filtration: a standard suitable for cutting fluids and belt filters

Nominal filtration is the most widely used method in industrial effluent treatment.

It guarantees the retention of an average percentage, typically 70% of particles corresponding to the announced threshold.

Advantages of nominal filtration:

- high flow rate,

- low pressure drop,

- high compatibility with belt filters,

- ideal for filtering cutting fluids, quenching baths, and grinding sludge,

- economical.

Nominal filtration is commonly achieved using:

- filter bags,

- non-woven media rolls.

Absolute filtration: definition, advantages, and uses

Absolute filtration retains virtually 100% of particles equal to or larger than the specified threshold.

It is essential in sectors where even the smallest particle can degrade the process.

Applications of absolute filtration:

- protection of high-pressure pumps,

- high-precision machining,

- final filtration before reinjection,

- highly demanding polishing and grinding.

Filter cartridges are often preferred for achieving an absolute filtration threshold of less than 10 μm.

Nominal filtration vs. absolute filtration: which choice for your effluents?

| Application | Recommended type | Recommended threshold |

| Bar turning | Nominal | 50–100 µm |

| Band filter for grinding | Nominal | 20–80 µm |

| Quenching bath | Nominal | 30–100 µm |

| HP pump protection | Absolute | 10 µm |

| Recycled cutting fluids | Nominal fine | 10–50 µm |

The choice depends on the level of cleanliness required, the degree of abrasiveness of the particles, and the format of the filter media used (roll, filter bag, or filter cartridge).

TSS rate: an essential indicator for industrial fluids

The TSS (Total Suspended Solids) level indicates the quantity of solid particles present in a fluid.

It is generally expressed in mg/L. Above 2 mg/L, the liquid is considered contaminated.

Why monitor TSS?

A high TSS level can lead to:

- rapid degradation of cutting fluids,

- a loss of machining quality,

- premature tool wear,

- clogging of nozzles or circuits,

- defects in grinding or lapping operations.

Filtration (using belt filters, filter bags, or filter cartridges) is the most effective method for reducing suspended solids and extending the life of industrial baths.

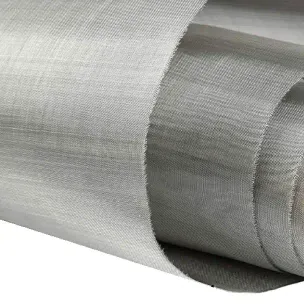

Filter media: a key factor in performance

The filter media directly affects the filtration threshold, the quality of the liquid, and the stability of the process.

It can be:

- non-woven (rolls for belt filters),

- polyester or polypropylene (filter bags),

- pleated (filter cartridges),

- high efficiency for absolute filtration.

Selection criteria:

- filtration threshold (5 to 500 µm),

- nature of particles to be retained,

- required flow rate,

- fluid temperature,

- chemical compatibility with cutting fluids or quenching baths.

FAQ – Frequently asked questions about cutting fluid filtration

🔹 What is a good filtration threshold for a cutting fluid?

Between 20 and 50 microns in nominal filtration for standard use, but this should be adapted according to the process. The experts at Filtres Monnet and Filtreri can guide you.

🔹 When should an absolute filtration cartridge be used?

When the process requires almost total particle removal – typically < 10 microns.

🔹 Which filter media should you choose for a belt filter?

The choice will depend on multiple factors: particle type, fluid type, flow rate, filter type (hydrostatic, gravity flat or pocket filter), TSS rate, filtration threshold objective.

🔹 Does the TSS rate influence machining performance?

Yes: the higher the MES, the faster the tools wear out and the more surface defects increase.

Conclusion: control the filtration threshold to optimize your industrial effluents

Understanding the filtration threshold, absolute filtration, MES levels, and the choice of filter media ensures cleaner, more stable, and more efficient industrial fluids.

Whether you use cutting fluid, quenching baths, or grinding and polishing baths, appropriate filtration—belt filters, filter bags, or filter cartridges —is essential for protecting your machines, reducing costs, and improving production quality.